Every business searches for tactics and opportunities that help them achieve significant success. Without change, business would remain stagnant or start to decline.

If you’re ready to grow your manufacturing business, there are several technological changes you can implement to improve your company’s productivity and profits.

Supply Chain Management Software

Effective supply chain management (SCM) tools are vital for manufacturers looking to enhance forecast accuracy, optimize inventory levels, and minimize lead times. These robust SCM software solutions offer real-time information and insights at every stage of the supply chain, providing complete visibility and control over operations.

By automating various SCM processes, businesses can streamline workflows, improve operational efficiency, reduce costs, and elevate customer satisfaction to new heights. Automation allows you to address potential obstacles, mitigate risks, and implement data-driven strategies that result in continuous improvements across the supply chain network.

Automation

Automation plays a vital role in modern manufacturing. Tasks once solely performed by humans are now efficiently handled by machines, including repetitive activities such as data entry and quality control. Automating these uncomplicated tasks gives employees substantial time to prioritize projects that require human input and creativity.

Implementing automation boosts productivity and enhances overall quality due to the reduction of human error and ample downtime. These improvements enable manufacturers to focus on optimizing operations and achieving higher levels of efficiency and excellence.

Predictive Troubleshooting Machines

As manufacturing processes become more complex, predictive troubleshooting is emerging as a vital technology. It leverages machine learning algorithms and historical data to predict potential faults and failures in machinery before they occur. By continually analyzing data streams from the machinery and comparing them to known failure modes, predictive troubleshooting systems can identify subtle changes that may indicate an impending issue.

This early detection allows for proactive maintenance, reducing unplanned downtime and enhancing overall productivity. It will also promote a prolonged lifespan by averting excessive wear and tear. The incorporation of predictive troubleshooting machines into a manufacturing setup can significantly boost operational efficiency and result in substantial cost savings.

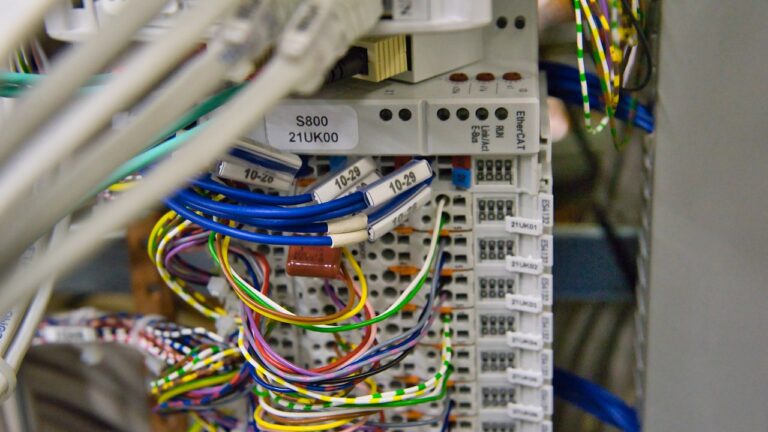

Programmable Logic Controllers (PLCs)

PLCs are essential in the manufacturing industry because of their advanced diagnostic and communication systems that enhance system performance. These are industrial digital computers designed for the control of manufacturing processes, such as assembly lines, robotic devices, or activities that require high-reliability control, easy programming, and processing fault diagnosis.

Programmable Logic Controllers can manage a wide range of input and output devices, allowing for the automation and control of complex processes and machinery. It’s also possible to program a series of commands into the system. It will automate these commands to reduce manual labor and increase precision.

Cloud-Based Manufacturing Software

Manufacturing software hosted in the cloud can provide significant benefits to manufacturers. Cloud-based software eliminates the need for expensive server hardware and reduces maintenance and support costs.

Cloud-based software is also accessible from anywhere, which makes it easier for employees to work remotely or on the go. Not to mention, it updates automatically. Your business will always have access to the latest features and security updates.

If you’re ready to see an increase in profit, efficiency, and customer satisfaction, incorporating these various technological changes will greatly improve your manufacturing business. Give these methods a try and watch your business thrive.